- Homepage

- Corporate

- PRODUCTS

- Agencies

- Career

- Contact

-

Edge Banding Machine

Products in the woodworking industry

are frequently used in areas such as furniture and construction. It goes

through many processes until it is made available to the end user.

One of the last processes before assembly

in the furniture industry is edge banding. In addition to the aesthetic surface

coating materials on wood-based boards, edge coating processes are performed in

order to give the aesthetic appearance on the surface to the edges. This

process is done with PVC, melamine, solid, papel, synthetic or coating

material.

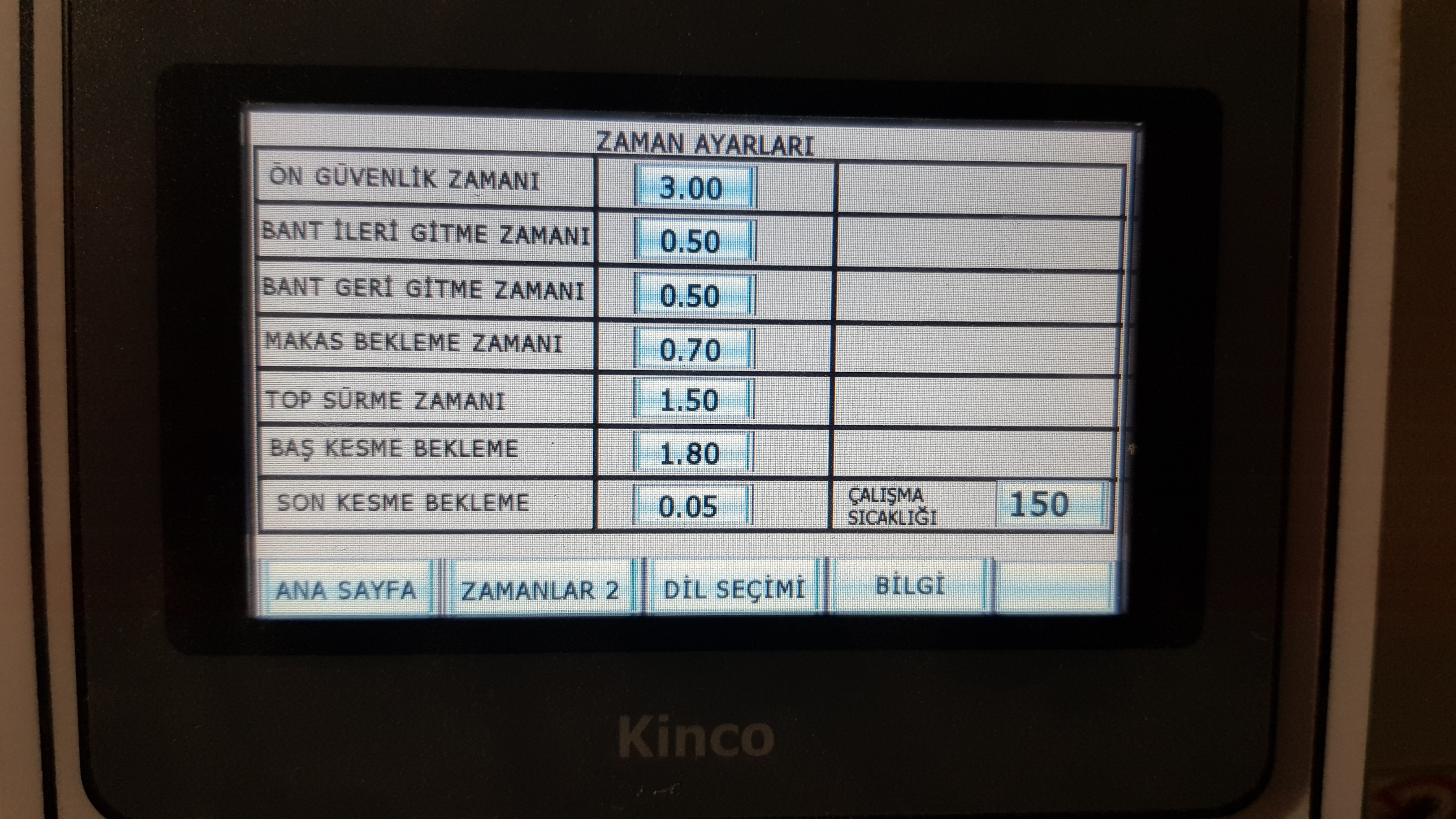

The system that melts the glue in

order to perform the edge banding process has a minimum temperature value. When

the necessary conditions are created, the glue melts and is applied to the

surface of the boards to adhere the banding material.

After glue is given with the edge banding material, processes are also applied to remove excess and form. During these processes, it tries to give the best form by adjusting it according to the thickness of the edge band and plate thickness.

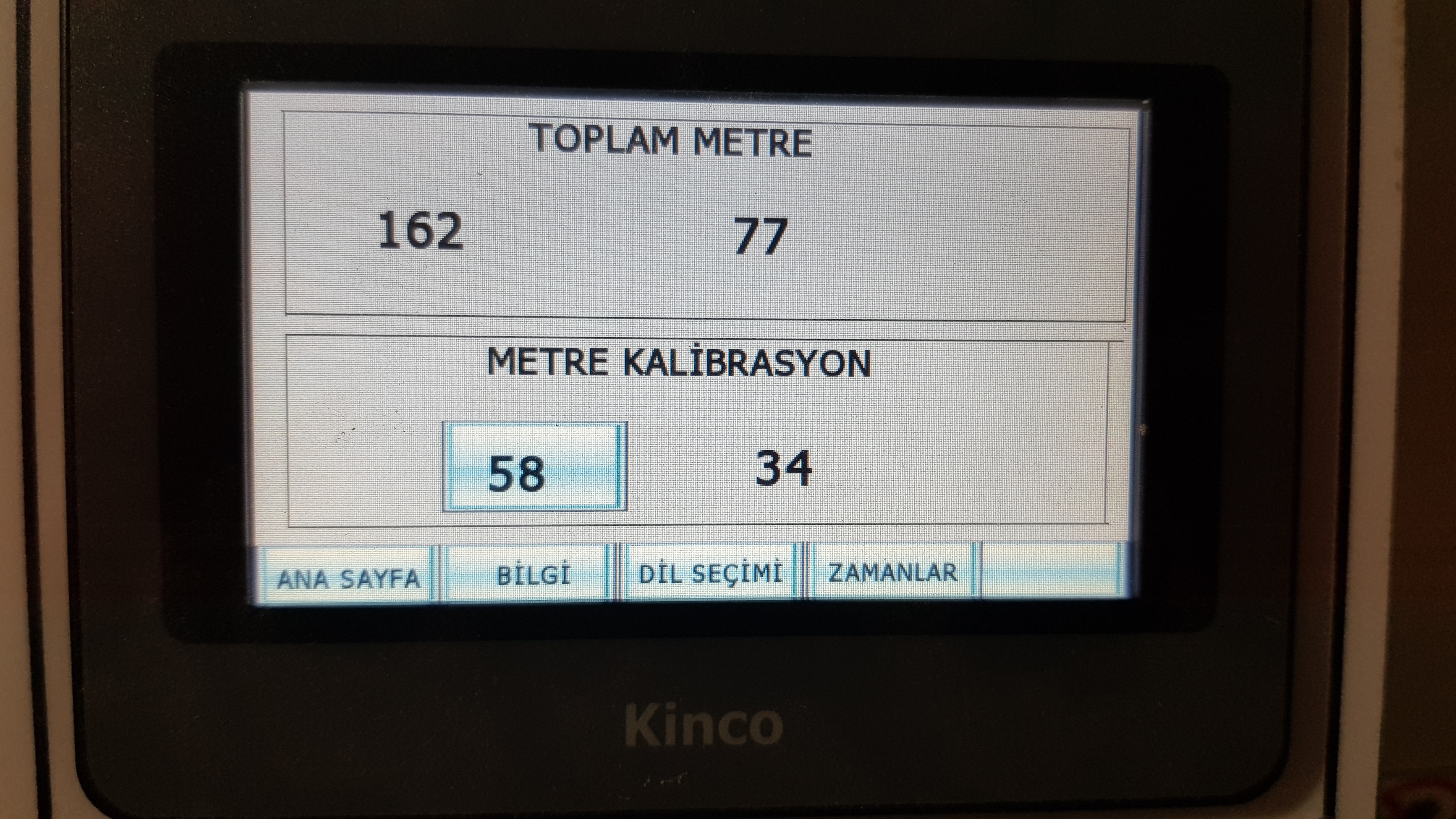

The work that users can finish in 2

days with manual banding can be completed in 3-4 hours with Edge Banding

Machines. At the same time, the user can check how many meters of edgebanding

has been done.

Kinco Touch Panel (HMI) and PLC

solutions are used in these systems. All controls are provided by the PLC Main

Unit and the heat sensor module connected to it.